History

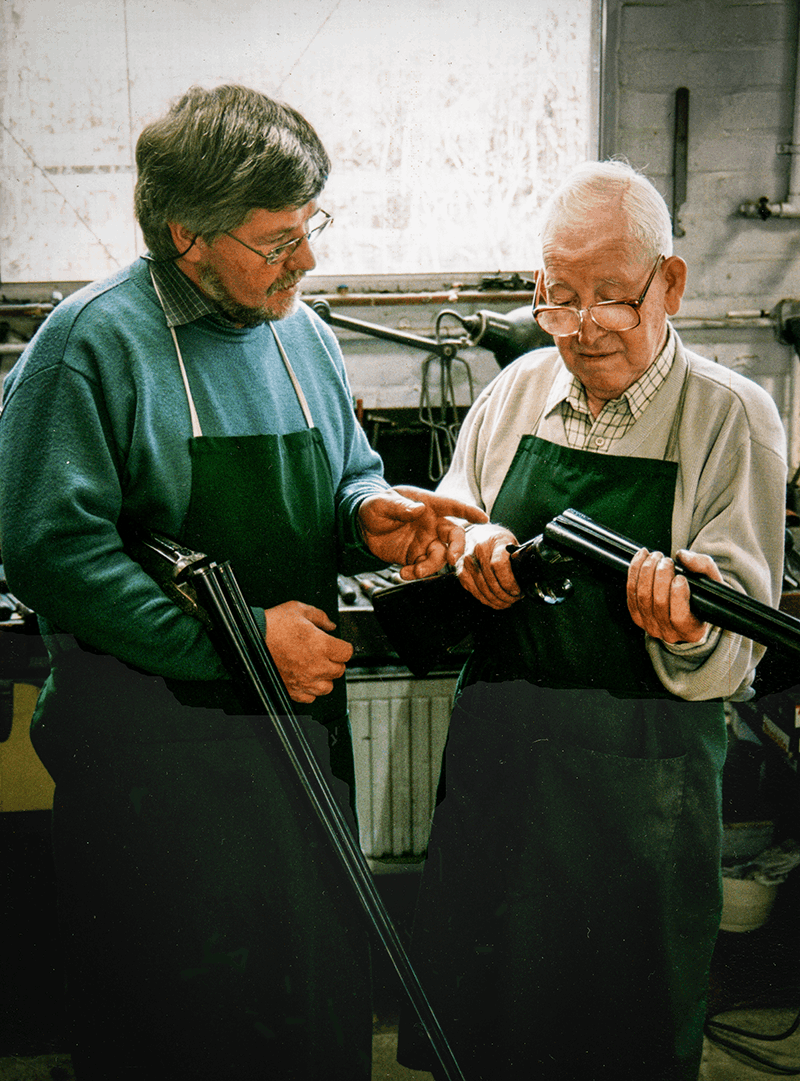

Only a handful of Birmingham gunmakers survived the Great Depression, the Second World War, and the period of austerity that followed. But one was established, survived, and ultimately succeeded during this difficult period for the trade. Albert Arthur Brown was the son of John Joseph Brown, a gunmaker who had at one time worked for Webley & Scott, B.S.A., and W. W. Greener and who ended his working career as resident caretaker with Greener.

The W.W.Greener factory, called The Prize Gun Works, Birmingham faced St. Mary’s Row with Loveday Street to the side. In the doorway of the picture in top left stands John Brown, Caretaker of Greeners for the last 20 years of his life. That this building should be demolished for city re-development seems such a crime now. It should just have been relocated instead! John was A.A.Brown’s father and was one of five sons all employed in the gun trade. Sidney recalls, as a small boy, visiting his grandfather on a Sunday and being taken through the factory to help with “the rounds”. “Mind that step” he would be told, “you’ll set off a blank if you tread on it!”.